AIREA TECH

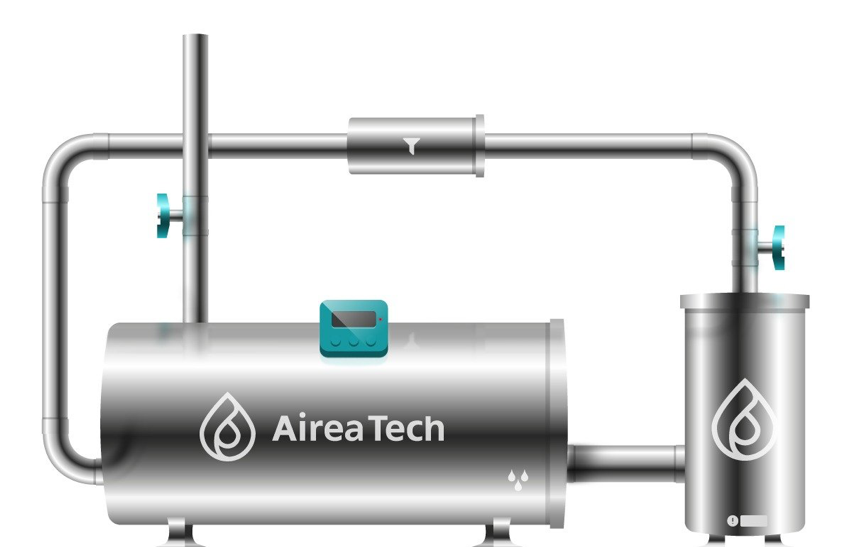

The “Airea Tech”, innovative S.r.l., has been constituted to develop, produce, and commercialize a flexible range of plants for the treatment of the emissions in the atmosphere with an excellent price/performance/consumption ratio. The basic product of “AireaTech” is a plant, patented, based on a study of air/water/ionization flows and applied on equipment for the purification of air, fumes, and gases in general. The evolution of the technology in the industrialization phase analyses the actual efficiency in a closed loop.

The machine has been studied for the continuous washing of the fumes in a closed cycle with nebulized and ionized water that results to be more effective compared to the use of non-ionized water even if additivities with chemical products. Ionized water is negatively charged (negative ions) and allows the abatement of fumes resulting from combustion as these are positively charged (positive ions). the term “cohesion” refers to the action of attraction between molecules of the same type. Both forces are electrostatic in nature.

In this way, greater filtration efficiency will be obtained: the filter will not be clogged by sludge which, as is well known, consists of important bacterial masses. In addition, the leaks from the vaporization plant will not pollute the environment and will drastically reduce the temperature of the emitted steam. This process will make the air healthier and cleaner for the operators but also fresher

Implant A.T.T. - Air Treatment Technology AIREA TECH

Project designed for the purification of emissions in continuous, using only ionized water in closed circuit, thanks to wet systems developed by us for the treatment of hot and cold emissions. It guarantees the abatement of numerous pollutants with averages equal to or greater than 90%, in addition to the abatement of the temperature of the fumes discharged into the atmosphere up to 20/25°.

Patented design

ITALY – “Patent application for industrial invention no. 102019000012099” filed on 17/07/2019 entitled “Process and plant for the treatment of a gas stream containing pollutants”. ITALY – “Patent application for industrial invention no. 102021000000683” filed on 15/01/2021 entitled “Process for the abatement of pollutants contained in a gas flow and related plant”.

Technical Features

- Reduced energy and management costs

- No chemical reagents of any kind are used

- Spare parts: there are no components subject to wear no filters to replace scheduled maintenance

- Cleaning: periodic replacement of water in the recirculation tank, sludge cleaning, and removal of materials.

- Components: static filtration – AISI 316 steel structure – AISI 316 steel nozzles – iron/steel aspirator – AISI 316 steel ionization.

Principle of operation

The innovative process, on which the operation of the wet scrubber is based, exploits the physical properties of the fluids inspired by normal wet scrubbers, but unlike the latter, thanks to a unique combination of technology and flow management, it reaches unthinkable yields for a normal scrubber. The product is modulable and customizable according to any mix of pollutants and/or any required flow rate. The pollutants present in the air are intercepted by the ionized water, thanks to the technology present in the scrubber. The output result is an effluent that contains all the pollutants present in the previously treated gas, thus avoiding emissions into the atmosphere.

The wastewater then enters the second and final part of the process where it is treated in several stages to separate concentrated pollutants. The purified and ionized water is then ready for the next cycle. The final state of the waste is a sludge that will be drained and stored for treatment and/or disposal according to law. ATT Technology, which stands for Air Treatment Technology, can be defined as a non-selective mechanical catalyst.

Transparent air is not clean

The greatest air pollution is that which humans produce to meet their civil and industrial needs. The various combustion processes used to cook food, heat, to power motor vehicles and machinery, produce the most widespread pollutants. Anthropogenic air pollution comes from large stationary sources (industries, power plants, and incinerators); small stationary sources (home heating systems); and mobile sources (vehicular traffic). Many of these sources are closely related to the production and consumption of energy, especially fossil fuels. The use of fossil fuels for domestic heating, especially heavy fuel oil, biomass, and coal is a significant source of environmental pollution of particulate matter and sulfur dioxide, especially in temperate regions (especially China and Eastern Europe).

The impact of pollutants on humans depends on where the pollutants are produced and where they are dispersed. Large stationary sources, often located far from larger population centers, disperse into the air at great heights, while domestic heating and traffic produce pollutants that are released at ground level in densely populated areas. As a result, mobile and small stationary sources contribute more to air pollution in urban areas and, consequently, are much more of a threat to public health than would be assumed by a simple quantitative comparison of emission types.

Cross-border pollution

Pollution does not respect national boundaries; therefore many countries are forced to suffer acid rain due to air pollution from other parts of the planet and which is transported for hundreds or even thousands of kilometers. The air is only the means of transport that with the formation of acid rain pollutes the land and all the water. High chimneys are (just hypocrisy) do not solve the problem, they move it somewhere else, The term acid rain generally refers to the process of fallout from the atmosphere of acidic particles, gases, and precipitation. If this acid deposition occurs in the form of precipitation (rainfall, snow, fog, dew, etc.) it is called wet deposition.

Methane boilers

Methane gas boilers in terms of emissions and particulate matter are the best fuel to use, however, it must be kept in mind that this does not mean that the products of combustion are “clean and healthy”, but that compared to other fuels such as diesel or wood are less harmful to the environment or health. A CNR research shows that boilers running on methane gas for domestic use, even with the premixed operation, however, produce a quantity of particulate matter between 1µm and 10µm. Methane gas, which is commonly used in the domestic, tertiary, industrial, electrical energy production, and automotive sectors, is an excellent fuel that, however, costs our planet dearly in terms of greenhouse gas emissions.

The “AireaTech” solution

The different types of waste incinerated in waste-to[1]energy plants and the many industrial processes give rise to combustion fumes increasingly rich in inorganic and organic pollutants, such as HCl, SOx, HF, NOx, heavy metals, dioxins, and furans, which must be “almost” completely abated to comply with the strict limits of the law. This process, therefore, requires increasingly complex systems that often use large and increasing amounts of chemical reagents and energy to break down these pollutants. The solution “Airea Tech” does not use chemicals of any kind and from our analysis, we obtain record performance even higher than 90% for the remediation of pollutant emissions into the atmosphere, a reduction of temperatures in the chimney with even higher % with a single step.

The innovation of the patent lies in its simplicity and can be sized and applied in many sectors: Heating, methane, LPG, diesel, and pellet boilers. Biomass, biogas, composting plants to generate energy Incineration plants, coal, or fossil fuel plants to generate energy, Air in semi-enclosed and/or underground environments Food, galvanic and chemical industry Hot and cold metal stamping and processing These are the sectors where “AireaTech” can address, activities and systems to produce different electrical, thermal, and other energies that share a big problem, emissions into the atmosphere.

One of our AireaTech projects is a natural gas emission purification island for thermal power plants, which allows us to maintain the filtration percentage always at 100%. This project has the objective of designing purification plants for boilers of entire condominiums.

AireaTech EcoVan

From the interest of promoting an environmental solution to intervene on air pollution from different combustions, the idea of proposing the project Airea Tech EcoVan was born. It is a new service designed to monitor and clean up the pollutants present in the air and to restore more correct environmental parameters both in our territory and in specific closed locations. EcoVan is a vehicle equipped with an A.T.T. washing system and instruments to analyze at least 15 pollutants (the most known ones) directly on site. The washing system is autonomous in its operation and can be operational in a short time. Initially, we intervene by identifying the pollutants and analyzing them, then we intervene for the treatment and finally we re-perform the analysis to verify the result obtained. This is a service aimed at both public bodies and the private sector.

Our service

Purify the air and monitor environmental parameters Analyse and compare pre and post-intervention parameters Install a fixed A.T.T. system or continue with periodic interventions Combine filters with our purification system through ionization, a system at the basis of our patent applications.

Who Is it for?

Thanks to the abatement of emissions without the use of chemicals and the transformation of pollutants into a continuously drained and expelled sludge, the wet scrubber can be sized and applied to many sectors:

Heating and Boilers

Biomass plants

Industrial plants

Energy production plants

Biogas plants